Quality wins

over any other strategy.

EUROSUOLE QUALITY, as the name implies, represents the quality that we ensure through both our products and the way we work. Eurosuole S.p.A. always prioritises product quality and high quality standards throughout our production process.

The WELLFEET brand indicates an extremely light, non-slip material that makes it possible to produce thick soles with excellent chemical-physical characteristics in terms of resistance to low temperatures and hydrolysis. A material we have studied and successfully introduced to the fashion sector. “The walking pleasure” is the claim for this brand, which communicates the effect of its soft plantar massage.

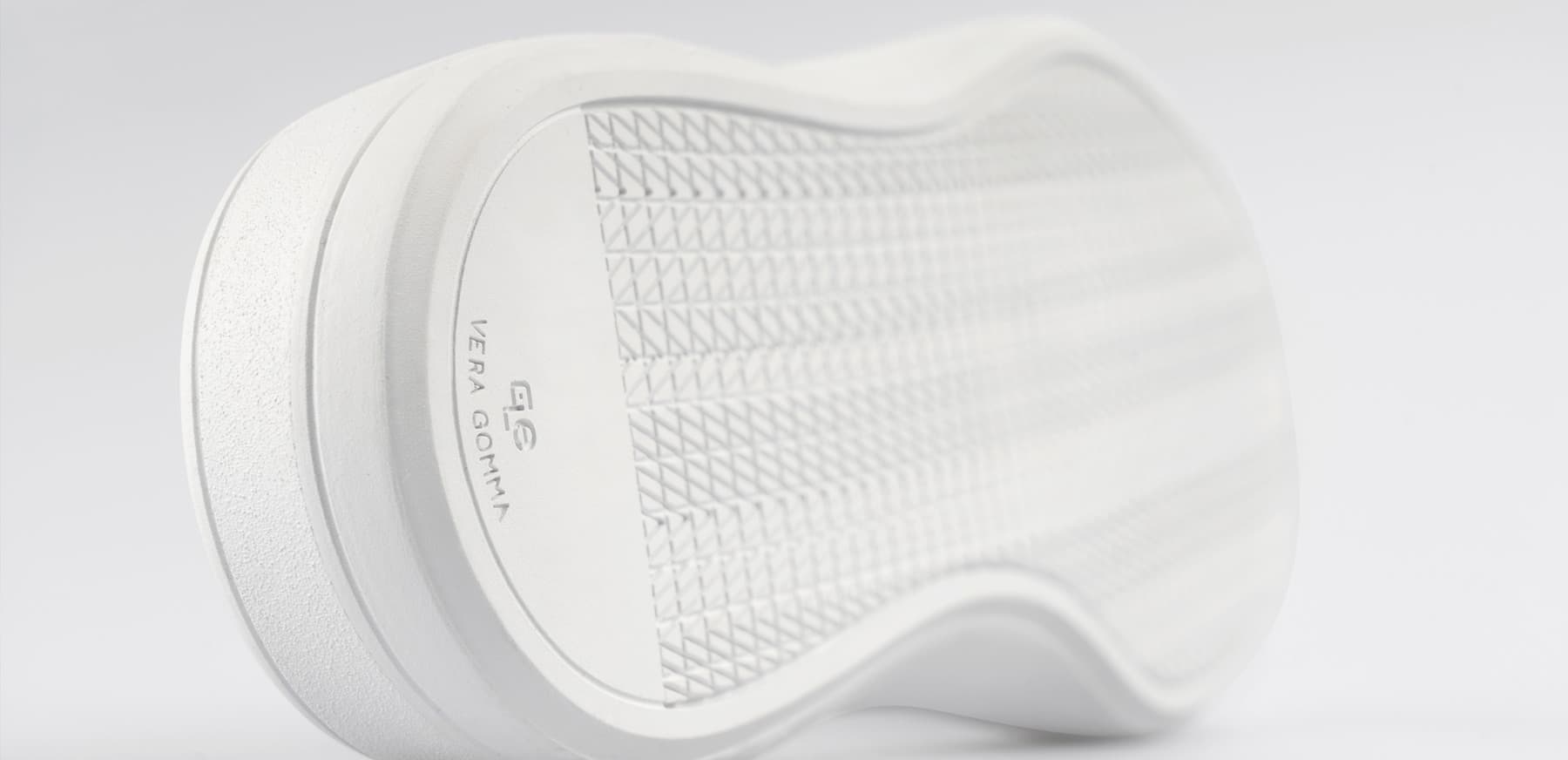

The GLE (Gomma Leggera Eurosuole, Eurosuole light rubber) brand is “the new dimension of lightness”, in other words a vulcanised foam rubber that guarantees dimensional stability and less weight than traditional rubber soles, without compromising on any characteristic. A product that therefore has all the same characteristics as rubber but a lighter weight thanks to its density, which can range from 0.60-0.90 gr/cm3.

FUTUR GREEN highlights the commitment by Eurosuole S.p.A. to sustainability, the aim being to reduce its carbon footprint thanks to the use of increasingly more eco-compatible alternatives. An eco-friendly material to decrease the consumption of materials extracted from crude oil in favour of those obtained from recycling.

Futur Green for polyurethane soles

The material used for the FUTUR GREEN blend is a polyurethane made partially from renewable sources. Part of the materials used derives in fact from plants, mainly from rape, a plant grown in Europe, and from sources that do not affect the food supply chain. This process has ecological value as it allows savings in fossil resources.

Futur Green for rubber soles

The material used for the rubber blend is obtained from “ground waste rubber” which promotes a correct process of circular economy able to turn materials that would have become landfill into new resources. After being ground, the waste is reused to create a new blend: the result is a secondary raw material.

Contact us to develop your product

We can meet any requirement you may have.